external oring installation machine automated o-ring installation machine

Brand: GLT

Country of origin: China

Technical Support: Longlife

Application: nozzles,connector,sprayer,valve,pump,lances,filter,filtration,fittings,irrigation,adapters,automation

external oring installation machine automated o-ring installation machine

oring installation machine

o ring installers

external o ring installation

internal o ring assembly machine

automated o-ring installation machine

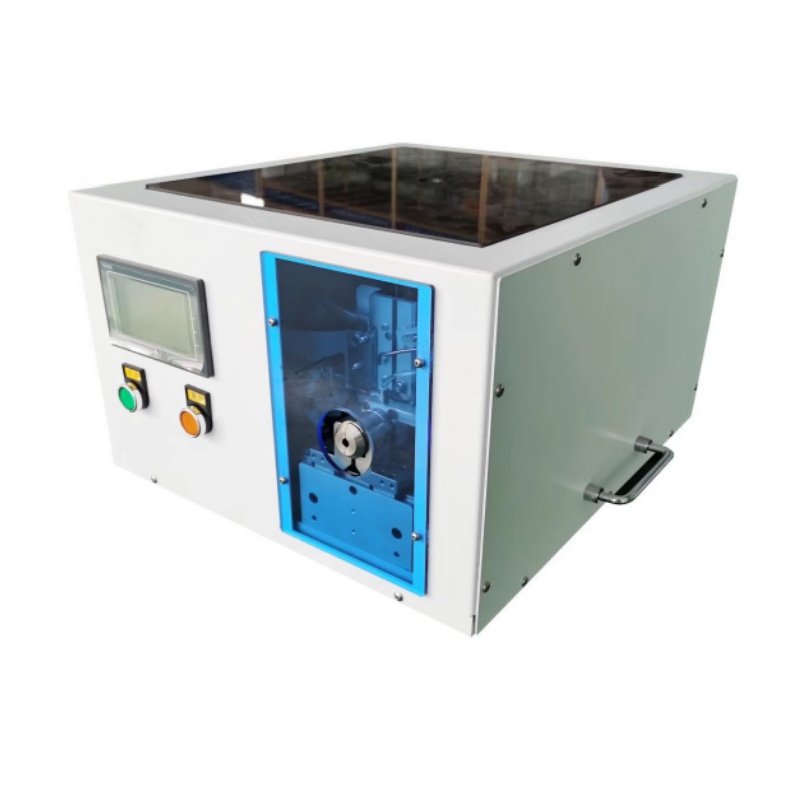

Automatic O ring installation machine JOA01

external oring installation machine automated o-ring installation machine

oring installation machine

o ring installers

external o ring installation

internal o ring assembly machine

automated o-ring installation machine

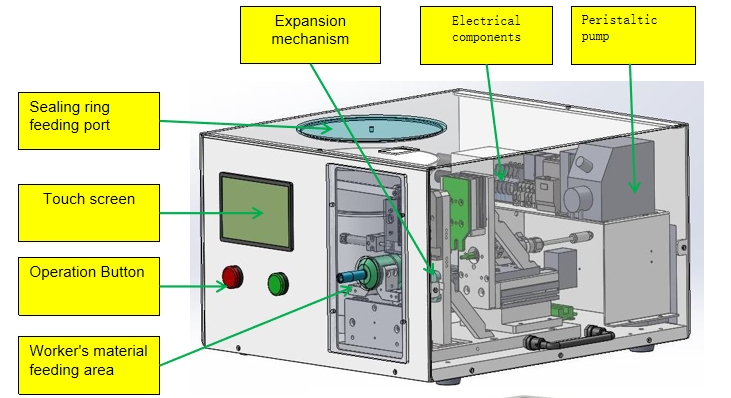

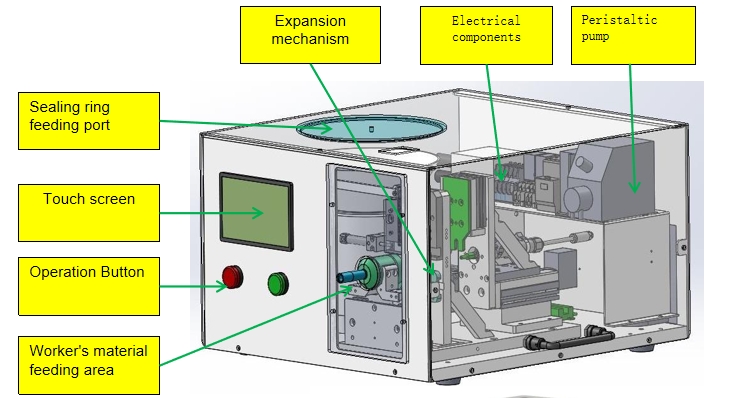

a. The equipment is equipped with an instruction manual when it leaves the factory, and customer related personnel are trained in its use and maintenance,mainly composed of a sheet metal shell, a sealing ring feeding system,a sealing ring expansion mechanism,and lubricating oil filling Components such as injection system and electrical control system;Reduces operator fatigue,Strong, compact frame,Easy integration into assembly production lines.

Application:

automotive, compressor, CPU liquid cooler,Evaporator,fliter,hydraulic,sanitary,sprayer

Main Features:

Automatic sealing ring assembly machine

1. Electric control systema. Adopting touch screen integrated machine control, the electrical part complies with relevant national safety standards;a. The main power switch, relays, buttons, etc. are made of high-quality brands, and the sensors are imported brands; b. Standard terminal blocks are used for electrical wiring and are accurately labeled;

2. Pneumatic systema.

The main pneumatic components such as cylinders, solenoid valves, air filters, etc. are made by Taiwan's Yadeke brand;The gas source is equipped with pressure stabilization, gas water separation, and impurity filtration treatment devices to ensure the dryness and purity of the gas source.3. Technical indicators

a. Feeding method: The sealing ring is fed by a vibrating disc

b. Control mode: touch screen all-in-one machine c. Factory humidity: ≤ 95% Factory temperature: 3-40 ℃ d. Compressed air pressure: 0.5-0.7MP e. Power supply parameters: AC220V ± 15%, frequency 50HZ ± 2% f. Production capacity: approximately 1000 pieces/hour g. Size: L500mm*W460mm*H300mm 70Kgs

Our o ring insertion machine is widely used in different applications,for example,nozzles,connector,sprayer,valve,pump,lances,filter,filtration,fittings,irrigation,adapters,automation.To do gasket ring installation,gasket ring assembling,seals installation,seals assembling, including external o-ring installation,internal o ring installation.We have both full automatic o-ring assembly machine,semi-automatic o-ring assembly machine.

Specifications:

| Machine name | Automatic O ring assembly machine |

| Item code | JOA01 |

| Input Voltage | AC220V 50HZ |

| Production capacity | 1200 pieces/hour |

| Air pressure | 0.5-0.7MP |

| Machine size | 50 x 46 x 30 cm |

| Machine weight | 70KGS |

| Package | Wooden box |