High Speed Flexible Wire Hose Braiding Machine

Brand: Benfa

Country of origin: China

Technical Support: Longlife

Application: sanitary, cable,car and motor hose,high-pressure hose industries,

Carrier Per Deck: 16,20,32,36,48

Braided Hose OD: 16,20,32,36,48mm

Greenland Benfa techology High Speed Flexible Wire Hose Braiding Machine

flexible hose braiding machine,high speed braiding machine,high speed hose braiding machine,High Speed Wire Braiding Machine

1, Automatic and fast speed.

2, Fully cover reduce noise

3, Easy to operate

4, less labor cost, one people can watch 10 machines together.

Download

Greenland Benfa techology High Speed Flexible Wire Hose Braiding Machine

flexible hose braiding machine,high speed braiding machine,high speed hose braiding machine,High Speed Wire Braiding Machine

Main feature:

Greenland Benfa techology High Speed Flexible Wire Hose Braiding Machine

flexible hose braiding machine,high speed braiding machine,high speed hose braiding machine,High Speed Wire Braiding Machine

It sounds like the Greenland Benfa technology High Speed Flexible Wire Hose Braiding Machine offers impressive features such as

High speed,

Automatic adjustments,

Efficient production.

The low noise and easy maintenance aspects make it user-friendly.

Customization options add flexibility to meet specific customer needs.

Specifications:

Greenland Benfa techology High Speed Flexible Wire Hose Braiding Machine

flexible hose braiding machine,high speed braiding machine,high speed hose braiding machine,High Speed Wire Braiding Machine

| Type | carrier per deck | carrier speed [RPM] | braiding machine power | haul off motor power | braiding pitch set up | carrier tension | braided hose OD | Weight |

| BFB16L-140CFS | 16 | 55rpm(max) | 1.5KW*2 | 0.75KW | electronic parameter set | 0.4kg-5.0kg | ≤16mm | 300kg |

| BFB20L_140B | 20 | 45rpm(max) | 1.5KW | mechanical variable speed drive | 0.4kg-5.0kg | ≤20mm | 350kg | |

| BFB20L_140B II | 20 | 45rpm(max) | 1.5KW | mechanical variable speed drive | 0.4kg-5.0kg | ≤20mm | 350kg | |

| BFB20L-140BF | 20 | 45rpm(max) | 1.5KW | mechanical variable speed drive | 0.4kg-5.0kg | ≤20mm | 350kg | |

| BFB20L-140CF | 20 | 44rpm(max) | 1.5KW | 0.55Kw | electronic parameter set | 0.4kg-5.0kg | ≤20mm | 350kg |

| BFB24L-140CFS | 24 | 42rpm(max) | 1.5KW*2 | 0.55KW | electronic parameter set | 0.4kg-5.0kg | ≤24mm | 580kg |

| BFB24L-140AF | 24 | 37rpm(max) | 1.5KW | mechanical variable speed drive | 0.4kg-5.0kg | ≤24mm | 380kg | |

| BFB24L-140AF II | 24 | 37rpm(max) | 1.5KW | mechanical variable speed drive | 0.4kg-5.0kg | ≤24mm | 380kg | |

| BFB24L-140B | 24 | 37rpm(max) | 1.5KW | mechanical variable speed drive | 0.4kg-5.0kg | ≤24mm | 380kg | |

| BFB24L-140B II | 24 | 37rpm(max) | 1.5KW | mechanical variable speed drive | 0.4kg-5.0kg | ≤24mm | 380kg | |

| BFB24L-140BF | 24 | 37rpm(max) | 1.5KW | mechanical variable speed drive | 0.4kg-5.0kg | ≤24mm | 380kg | |

| BFB24L-140CF | 24 | 42rpm(max) | 1.5KW | 0.55KW | electronic parameter set | 0.4kg-5.0kg | ≤24mm | 380kg |

| BFB20L+24L-140CFS I | 24 | 37rpm(max) | 1.5KW*2 | 0.75KW | electronic parameter set | 0.4kg-5.0kg | ≤24mm | 700kg |

| BFB24L+24L-140CFS I | 24 | 37rpm(max) | 1.5KW*2 | 0.75Kw | electronic parameter set | 0.4kg-5.0kg | ≤24mm | 700kg |

| BFB24L-140CS | 24 | 37rpm(max) | 1.5KW*2 | 0.55Kw | electronic parameter set | 0.4kg-5.0kg | ≤24mm | 630kg |

| BFB24L-140D | 24 | 37rpm(max) | 1.5KW | mechanical variable speed drive | 0.4kg-5.0kg | ≤24mm | 380kg | |

| BFB24L-140DI | 24 | 37rpm(max) | 1.5xW | mechanical variable speed drive | 0.4kg-5.0kg | ≤24mm | 380kg | |

| BFB32L-140A | 32 | 28rpm(max) | 2 2KW | mechanical variable speed drive | 0.4kg-5.0kg | ≤32mm | 430kg | |

| BFB32-140B | 32 | 28rpm(max) | 2 2KW | mechanical variable speed drive | 0.4kg-5.0kg | ≤32mm | 430kg | |

| BFB32L-140CF | 32 | 28rpm(max) | 2.2KW | 0.75KW | ectronic pararmeter set | 0.4kg-5.0kg | ≤32mm | 430kg |

| BFB36L-140AF | 36 | 29rpm(max) | 2.2KW | mechanical variable speed drive | 0.4kg-5.0kg | ≤36mm | 520kg | |

| BFB36L-140B | 36 | 29rpm(max) | 2.2KW | mechanical variable speed drive | 0.4kg-5.0kg | ≤36mm | 520kg | |

| BFB36L-140BF | 36 | 29rpm(max) | 2 2xw | mechanical variable speed drive | 0.4kg-5.0kg | ≤36mm | 520kg | |

| BFB36L-140CF | 36 | 29rpm(max) | 2.2KW | 0.75KW | electronic parameter set | 0.4kg-5.0kg | ≤36mm | 520kg |

| BFB36L-140D | 36 | 29rpm(max) | 3.0KW | mechanical variable speed drive | 0.4kg-5.0kg | ≤36mm | 520kg | |

| BFB48L-140B | 48 | 25rpm(max) | 3.0KW | mechanical variable speed drive | 0.4kg-5.0kg | ≤48mm | 550kg | |

| BFB48L-140CF | 48 | 25rpm(max) | 3.0Kw | 0.75KW | electronic parameter set | 0.4kg-5.0kg | ≤48mm | 550kg |

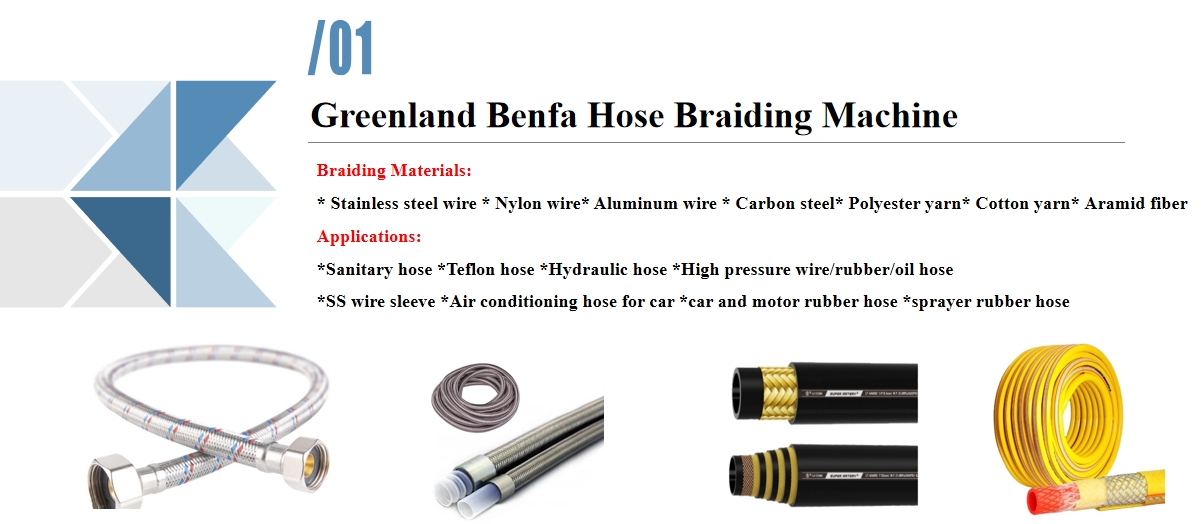

Applications:

Greenland Benfa techology High Speed Flexible Wire Hose Braiding Machine

widely use in different industries,such as sanitary hose , high pressure wire/rubber/oil hose, Teflon hose,

SS wire sleeve, air conditioning hose , car and motor rubber hose, sprayer rubber hose and so on.

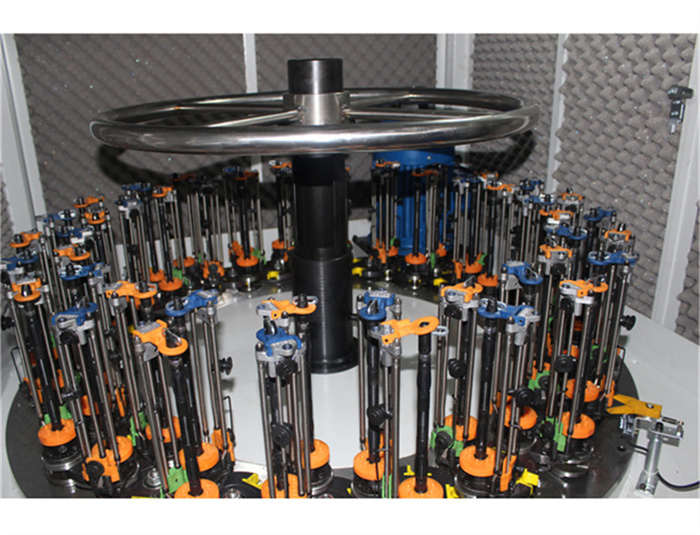

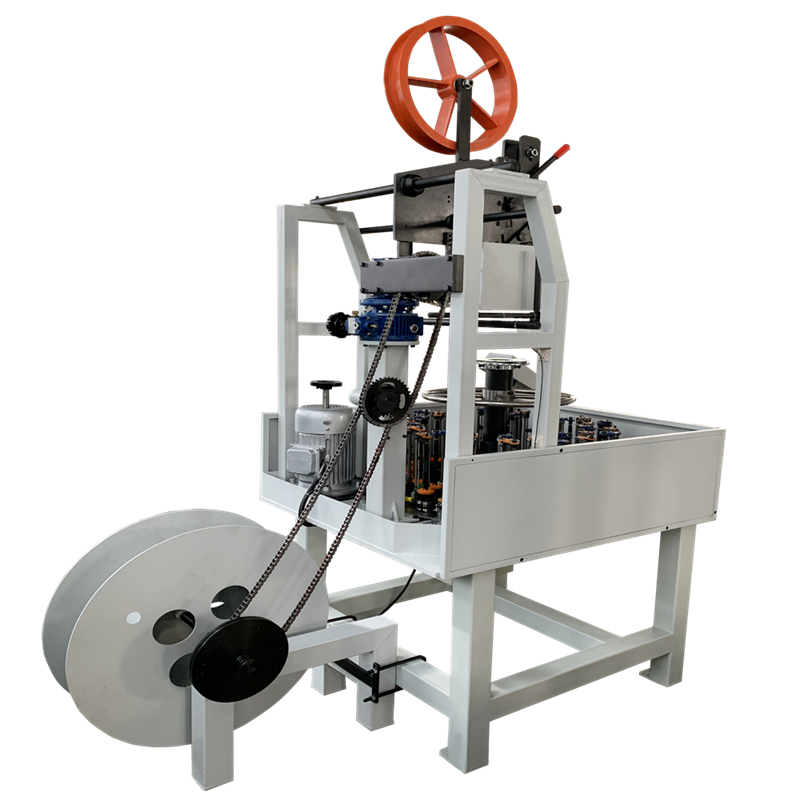

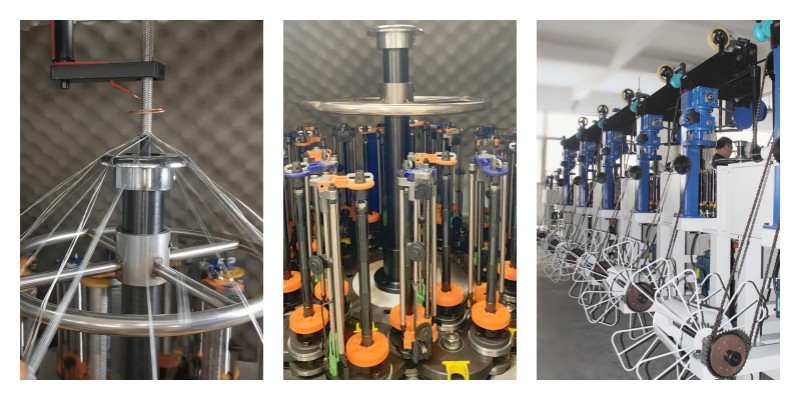

Product Detail:

Greenland Benfa technology hose braiding machine details as below photos:

Description:

Greenland Benfa technology hose braiding machine140L:with horn gear OD140mm,suitable for bobbin OD ≤ 82mm

Greenland Benfa techology High Speed Flexible Wire Hose Braiding Machine

flexible hose braiding machine,high speed braiding machine,high speed hose braiding machine,High Speed Wire Braiding Machine

carriers per deck | bobbin dimension |

8-96 | 80×28×277mm |

carrier speed [RPM] | bobbin capacity |

20-55 | 130 cm3-360 cm3 |

**Greenland Benfa's 140L Series Vertical Hose Braiding Machine:**

Introducing the Greenland Benfa Technology High Speed Flexible Wire Hose Braiding Machine, an innovative solution at the forefront of flexible hose manufacturing.

This high-speed braiding machine is designed for efficiency, safety, and ease of operation, addressing key challenges in the industry.

The automatic and fast-speed features of this machine set it apart, ensuring a streamlined production process. Crucially, it incorporates intelligent technology that

automatically stops the machine and triggers alarms in the event of issues like broken wire, depletion of wire, or the absence of tubing or rubber sheet.

This robust safety mechanism underscores its commitment to maintaining a secure and hazard-free working environment.

To complement its safety features, the machine boasts a fully covered design aimed at noise reduction. Extensive testing has confirmed noise levels as low as 78dB for

the enclosed braider. The incorporation of noise and shock-absorbing elements further contributes to a quieter and more comfortable operational setting.

Ease of operation is a standout feature, particularly in the context of rising labor costs and challenges in finding experienced staff.

The Greenland Benfa Technology High Speed Flexible Wire Hose Braiding Machine is designed for user-friendliness, enabling a single operator to effectively monitor

and manage 8-10 machines simultaneously. This efficiency is a valuable asset in the current labor market.

The machine's production capacity is a key highlight, catering to the demands of a dynamic industry. The carriers per deck range from 8 to 96, providing flexibility to

accommodate various production scales. The bobbin dimensions of 80×28×277mm, carrier speed ranging from 20 to 55 RPM,

and a bobbin capacity spanning from 130 cm³ to 360 cm³ contribute to the machine's adaptability and efficiency.

In conclusion, the Greenland Benfa Technology High Speed Flexible Wire Hose Braiding Machine represents a significant advancement in vertical hose braiding technology.

Its automatic features, emphasis on safety, low noise operation, user-friendly design, and high production capacity position it as a reliable and innovative solution

in the realm of flexible hose manufacturing.