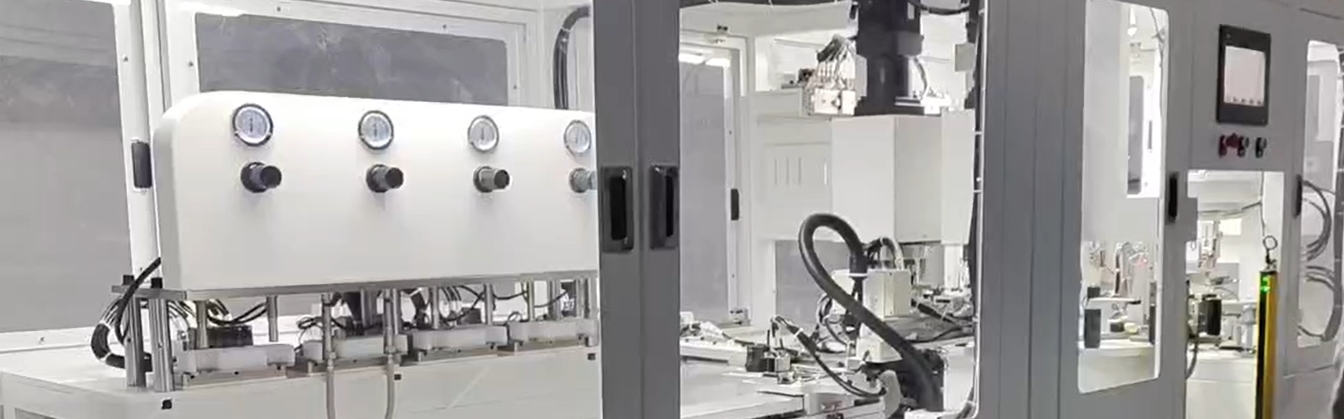

Automatic 3 in 1 electrical air industrial hose assembly machine

Brand: Benfa

Country of origin: China

Technical Support: Longlife

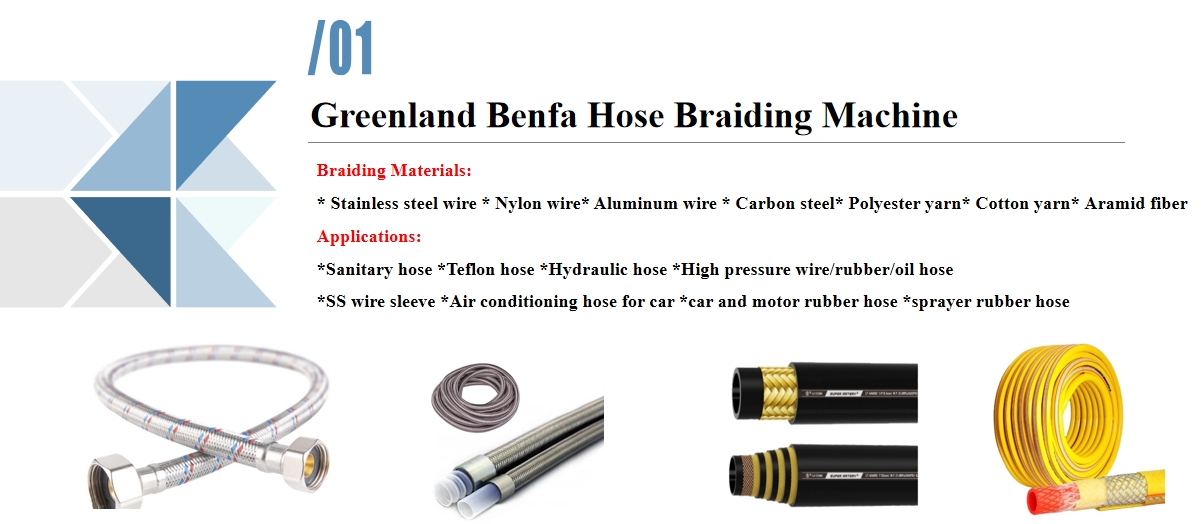

Application: *Sanitary hose *Teflon hose *Hydraulic hose *High pressure wire/rubber/oil hose *SS wire sleeve *Air conditioning hose for car *car and motor rubber hose *sprayer rubber hose

automatic 3 in 1 electrical air industrial hose assembly

Download

Greenland Benfa technology automatic 3 in 1 electrical air industrial hose assembly hydraulic hose crimping machine

3 in 1 electrical & air hose assembly

automatic industrial hose assemblies

Hose Assembly Machine

Main feature:

Greenland Benfa technology automatic 3 in 1 electrical air industrial hose assembly hydraulic hose crimping machine

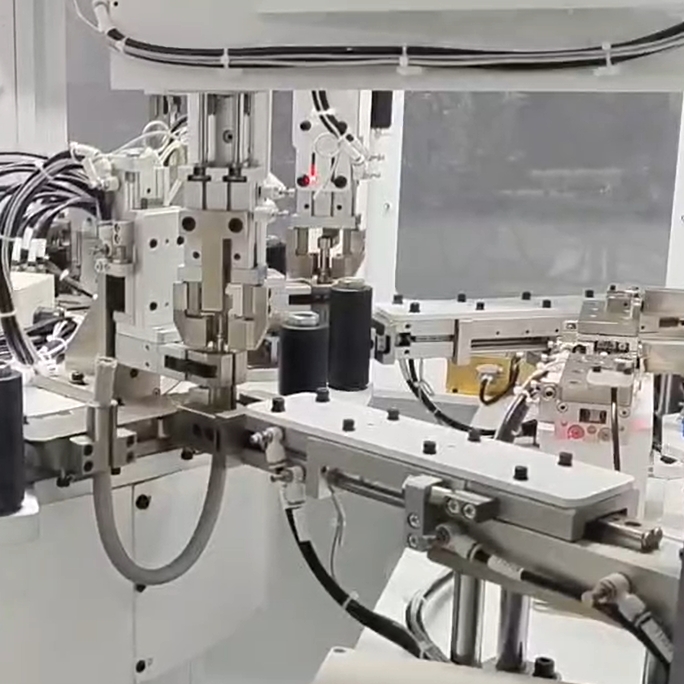

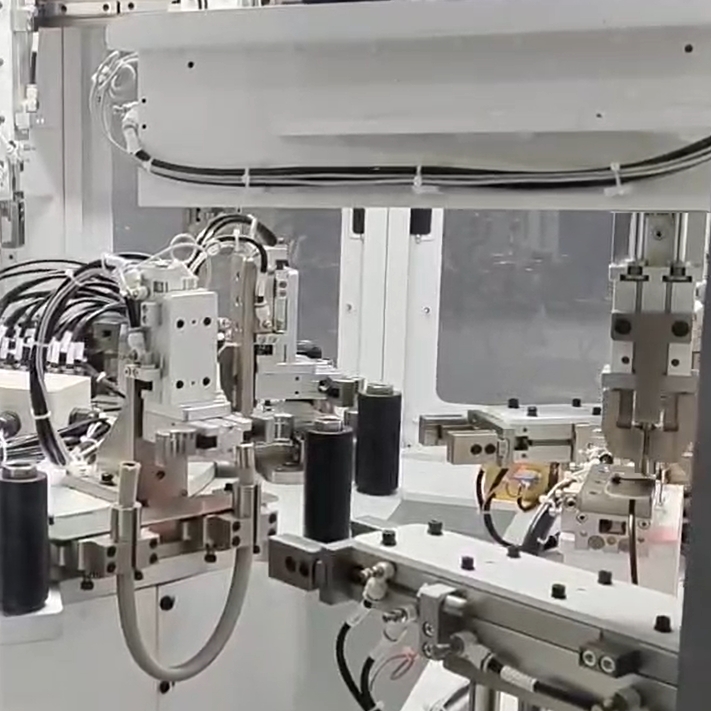

Steady pressure and easy to adjust.

High automatic and speed, adopt touch braking way。

Wind cool the hydraulic oil, stable pressure.

Crimper good looking, crimper dimension stable and controllable。

Digital display, show the pressure, production and temperature

Greenland Benfa technology hose braiding machine widely use in different industries,such as sanitary hose , high pressure wire/rubber/oil hose, Teflon hose,

SS wire sleeve, air conditioning hose , car and motor rubber hose, sprayer rubber hose and so on.

Description:

Greenland Benfa technology automatic 3 in 1 electrical air industrial hose assembly,hydraulic hose crimping machine

Greenland Benfa's Auto Rubber Hose Crimper Assembly Machine is distinguished by its exceptional features.

The assembly machine ensures steady pressure with easy adjustability, providing optimal control.

Operating at high speed, it employs a touch braking mechanism for seamless automation.

The integration of a wind cooling system maintains hydraulic oil stability, ensuring consistent pressure.

The crimper boasts an appealing design, and its dimensions remain stable and controllable for precision.

With a digital display, users can monitor pressure, production details, and temperature, enhancing overall operational transparency and efficiency.

This machine stands out for its reliability and advanced features in rubber hose assembly.