8 Heads Conduction Band Braiding Machine

Brand: Benfa

Country of origin: China

Technical Support: Longlife

Application: * communications cable * signal cable * USB cable * high temperature wire * insulation wire * iron wire * special cable * Rice cooker power cable * conduction band * shielded cable * control cable shielding layer of cable * coaxial cable.

Carrier Per Deck: 8,12,24,36

Greenland Benfa technology 8 Heads Conduction Band Braiding Machine

1.Reduce yarn waste due to auto stop system

2.High output/low maintenance

3.Reliable in continuous operation

4.Longevity thanks to an oil-bath construction

5.Auto stop system

Download

Greenland Benfa technology 8 Heads Conduction Band Braiding Machine

Product Description:

The 8 Heads Conduction Band Braiding Machine is a specialized and efficient piece of equipment designed for the precise braiding of conduction bands, typically used in various applications where electrical conductivity is crucial. This machine is equipped with eight braiding heads, allowing for simultaneous and uniform braiding, making it suitable for high-volume production. Here are the key features and details about the product:

Product features:

Conduction Band Braiding:

The machine is optimized for the simultaneous braiding of conduction bands, ensuring uniformity and precision in the braiding process.

Eight Braiding Heads:

Equipped with eight braiding heads, allowing for high-speed and efficient production. The multiple heads work simultaneously, enhancing productivity.

Wire Compatibility:

Capable of handling various wire types and sizes used in conduction bands, accommodating different materials and configurations to meet diverse industry requirements.

High-Speed Operation:

Designed for high-speed braiding suitable for industrial-scale production, ensuring rapid manufacturing of conduction bands.

Adjustability:

Adjustable settings for varying band diameters, lengths, and wire thicknesses. This adaptability is crucial for meeting the specific production needs of different conduction band applications.

Precision Tension Control:

Incorporates precise tension control mechanisms for each braiding head to maintain uniform braiding quality. This is essential for the integrity of the final product.

User-Friendly Interface:

Features an intuitive and user-friendly control panel for easy operation. Operators can set parameters and monitor the braiding process effortlessly.

Quality Control:

Real-time monitoring features and quality control mechanisms to ensure the production of high-quality and reliable conduction bands.

Energy-Efficient Operation:

Incorporates energy-efficient components and modes, contributing to sustainable and cost-effective operation.

Maintenance and Support:

Designed for easy maintenance with readily available support and spare parts. Regular maintenance is essential for prolonged machine life and consistent performance.

Compliance with Standards:

The machine complies with industry standards and regulations for the manufacturing of conduction bands, ensuring product quality and safety.

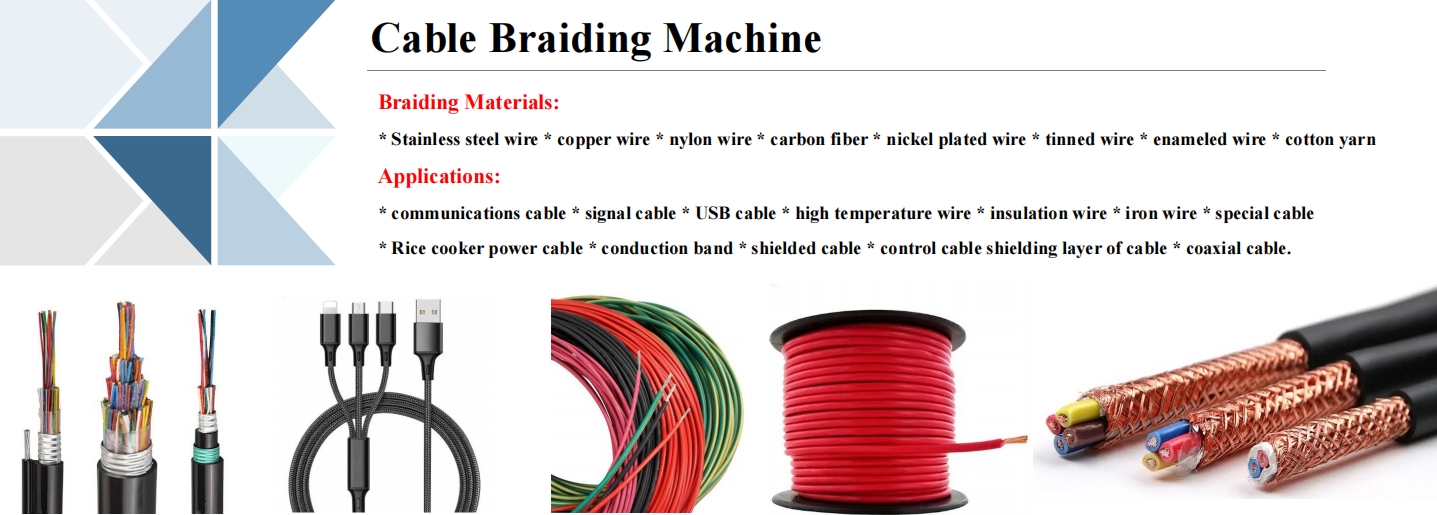

Braiding Materials:

* Stainless steel wire * copper wire * nylon wire * carbon fiber * nickel plated wire * tinned wire * enameled wire * cotton yarn

Applications:

* communications cable * signal cable * USB cable * high temperature wire * insulation wire * iron wire * special cable

* Rice cooker power cable * conduction band * shielded cable * control cable shielding layer of cable * coaxial cable.

Main Feature:

1. High degree of automation: automatic shutdown when broken wire, Wireless spool, without rubber hose.

2. The braiding traction adopts step less speed regulation,the braiding angle (pitch) adjustment is convenient and correct.

3. High production efficiency: the output per hour is more than three times of the current commonly used models. The maximum output is 98 meters/hour.

4. Low noise: the transmission system uses suction, shock absorption and embedded devices to reduce noise.

5. Convenient maintenance, flexible transmission, easy assembly and disassembly of structure.

6. The spindle adopts elastic adjustable device, which ensures reliable positioning and convenient and flexible loading and

unloading of spool.

7. The whole machine has small abrasion and long service life. The key parts are heat treated with high-quality materials and equipped with automatic lubrication device.

The 8 Heads Conduction Band Braiding Machine is a specialized solution for manufacturers in industries where precise and efficient braiding of conduction bands is essential. With its multiple braiding heads and advanced features, it is suitable for applications ranging from electronics to telecommunications, where high-quality and uniformly braided conduction bands are required.

Please do not hesitate to contact us, We can provide detailed information based on your specific requirements and applications.